Why We Went from 1 Factory for the World to the World Is Your Factory

In just five years, the world has turned upside down. Leadership has evolved from believing free trade was best to a world of tariffs, export restrictions and trade wars.

China has been (and largely still is) the factory for the world. But supply chain leaders are being pushed and prodded to see the rest of the world as their factory.

In Part 1 of this blog, I explained how this has happened. Today, in Part 2, I will explain why you must redesign global supply chains.

Basically, Adam Smith, the father of free trade, says so.

You might object. After all, aren’t all of these rules, regulations, restrictions and tariffs anathema to free trade?

Well, yes. But in perusing Adam Smith’s writings, I discovered four exceptions. In some instances, the Scottish economist/philosopher recommended interrupting free trade for:

- Protecting national security.

- Preventing economic upheaval.

- Ensuring imports are properly taxed.

- Retaliating against tariffs.

For the first time in history, all four of Adam Smith’s exceptions are in play. In these circumstances, even he called upon governments to intervene in free trade. And in these times, companies view nearshoring, friendshoring and reshoring as critical strategies for their future.

Philosophically, Smith preferred a level playing field. But sometimes that field is not level.

In other words, “The World Is Flat, Except When It Isn’t.”

Let’s examine the four exceptions. (For Part 1 of this blog, click here.)

National Security: Chip Wars and Pharmaceuticals

If you have a problem with another country, responsible leaders must ensure that your adversary does not turn that into an unfair advantage.

Over the last few years, Western leaders have grown more concerned about China. The country has ramped up aggressive moves and rhetoric toward U.S. allies Taiwan and the Philippines. Worries revolve around China’s dominance in many raw materials (especially for pharmaceuticals) and access to high-end semiconductor chips for weapons of war.

Virtually every offensive and defensive weapons system relies on semiconductors, according to the experts at Defense News magazine. The magazine quotes Chris Miller, author of the book Chip War, saying, “The future of war will be defined by computing power.”

The U.S. government has tackled the semiconductor issue in two ways, The New York Times reported:

- Restricting exports: The U.S. seeks to cut off China’s access to high-end chips and chipmaking equipment.

- Subsidizing chip manufacturing: $50 billion in direct funding, loans and loan guarantees to research and make high-end chips in the United States.

For pharmaceuticals, the U.S. is partnering with countries like India to develop alternative sources of production, according to The India Times. Post-pandemic legislation also has targeted what critics call “dependence on foreign drug manufacturers.” Businesses must respond by redesigning global supply chains.

Preventing Economic Upheaval Goes Hand in Glove with PPE

On a level playing field, Smith’s concept of comparative advantage reigns supreme. But nations occasionally face problems that require governments to step in.

This exception from Smith also included protecting workers in certain industries from sudden, unexpected economic disruption. But that is a temporary exception.

In my mind, a longer-lasting exception involved the 2020 pandemic.

China manufactured most personal protective equipment (PPE). China shut down. According to the CDC, U.S. healthcare facilities then struggled to provide PPE to frontline workers. Nurses, doctors and emergency personnel were often left unprotected.

In response, the CDC has developed a series of strategies healthcare facilities can use to conserve PPE during emergencies. Innovative public-private partnerships, documented by the Department of Homeland Security, also helped alleviate the shortage.

Post-pandemic initiatives have not worked as well. The U.S. still relies on Asia for PPE.

In fact, NPR reported on a $123 million grant to build a factory to make fake rubber for medical-grade disposable gloves. In addition, nearly $100 million in subsidies built a glove-making plant outside Baltimore.

Both factories stand idle. Federal funding has stalled. U.S. healthcare facilities have gone back to buying gloves from foreign manufacturers.

This is another example of good government intentions being swept aside by reality. PPE truly is a national security issue where federal initiatives could make a difference in preparing for the next disruption.

Instead, despite millions in taxpayer subsidies, the U.S. remains unprepared. Businesses must redesign their supply chains.

Ensuring imports are properly taxed

Smith wrote that imported goods need to face taxes similar to those faced by domestic goods.

In other words, say the U.S. government slaps a 10% tax on shoes made in South Carolina. Whether that’s a good decision is a topic outside the scope of this blog. However, shoes imported from Malaysia should face similar tax rates.

The U.S. government, in particular, has been heavily involved in import taxes and customs duties since 2011.

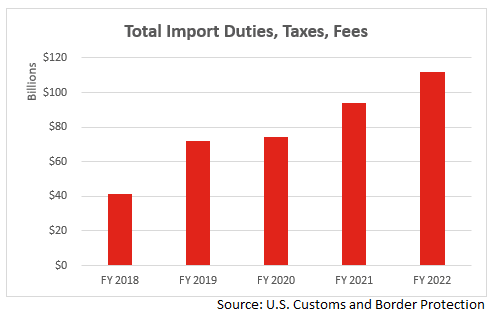

U.S. Customs and Border Protection reported that import tariffs increased from $41.6 billion in 2018 to $111.8 billion in 2022.

Retaliating against tariffs

At times, governments try to protect domestic industry by heavily taxing imports. This, of course, makes the world unflat.

Tariffs invite retaliation, something the world has seen plenty of over the last decade. Ideally, this retaliation invites other governments to reduce their tariffs, flattening the world.

Presidents Bush and Trump both enacted tariffs on steel and aluminum. Trump went even further, adding tariffs to an entire range of categories that included washing machines and solar panels. President Biden has not rescinded most of Trump’s tariffs.

The goal is to force the other country to rescind tariffs. Or, in the case of Bush and Trump, to encourage foreign countries to buy more U.S.-produced goods.

The goal, of course, is not a trade war. Despite what some say, nobody wins a trade war. And tariffs are just taxes on the end customer, not a penalty for individual countries.

Whether retaliatory tariffs hurt or help is another question entirely. In fact, media outlets are full of stories detailing how increased raw material costs for steel or aluminum hampered domestic manufacturers.

Heed Adam Smith; Avoid Catastrophe

You may agree or disagree with Adam Smith. Either way, government and corporate leaders are simultaneously dealing with his four exceptions to free trade. Although we wish the world was a flat, level playing field, it really is not.

This unbelievable amount of VUCA (volatility, uncertainty, complexity, ambiguity) now has the chance to block trade between hemispheres.

Right now, war threatens the Suez Canal and drought threatens the Panama Canal. These two key waterways connect hemispheres. Tensions between China and Western allies like Taiwan and the Philippines are increasing.

Suez was closed for eight years between 1967 and 1975. That sort of closure would devastate supply chains even more than today’s pandemic-induced problems. A war in Southeast Asia would be even more catastrophic.

So, if your company is doing the same things you were doing five years ago, your executives are messing up. The world is a totally different place.

Per Adam Smith, you must redesign your entire global network – sourcing, production, suppliers, distribution. Deploying optionality as never before is the only way your organization will deliver through the next disruption.

Contact me today and let’s discover your options. Don’t wait for global events to curtail your operations.

Related Reading

- Part I: From 1 Factory for the World to the World Is Your Factory

- A 3-Pack of Supply Chain Disruptions for the Holidays

- Profitability or Loyalty? What’s the Most Important Success Factor?

- How Return-to-Office Policies Could Fuel Your Competition

Jim Tompkins, Chairman and founder of Tompkins Ventures and Tompkins Solutions, is an international authority on designing and implementing end-to-end supply chains. Over five decades, he has designed countless industrial facilities and supply chain solutions, enhancing the growth of numerous companies. Jim earned his B.S., M.S. and Ph.D. in Industrial Engineering from Purdue University.