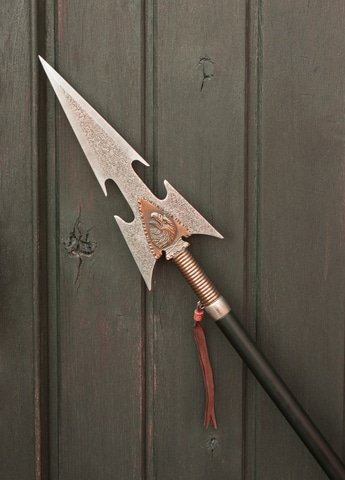

This Sharp Blade Can Deliver Supply Chain Resilience and Innovation

Militaries refer to their elite units as the “tip of the spear.”

These crack troops often lead dangerous, offensive missions. Think of the first waves of Americans, Brits and Canadians who waded through Normandy’s beaches 80 years ago on D-Day.

In the context of business and sales, “tip of the spear” refers to the most advanced or innovative part of a company, product line or strategy. It also can mean the first point of contact.

So what is the “tip of the spear” for procurement purposes?

Well, we think procurement can give your company a unique edge, a competitive advantage. Procurement done right can become the forefront of innovation, change or strategic initiatives, can drive profitable growth and increase market share.

Procurement can be your “tip of the spear” for 5 reasons:

- Resilience

- Optionality

- Sustainability

- Innovation

- Nearshoring and friendshoring

What is Procurement?

But first, let’s clear up what “procurement” really is.

Many commentators confuse sourcing and procurement, putting purchasing somewhere in the mix. But the definitions are really quite simple

Procurement is the overall process of acquiring goods, services or raw materials for an organization. The procurement process combines sourcing and purchasing.

Purchasing is the specific function within procurement that involves buying materials, goods or services from suppliers.

Sourcing strategically selects and manages suppliers to ensure a reliable supply of materials, goods or services.

Procurement Done Wrong: Bad Outcomes, Bad Publicity

Procurement practices often define how the marketplace perceives your reputation. You can spend a lot of money on marketing to try and affect what people say about your company.

But you waste that spend if you don’t pay your vendors on time, shut down factories, and are difficult to work with or play in ethical gray zones.

You know what the media will focus on? The subpar way your procurement operates, not your marketing message.

That’s critical to know, because many companies spend more on procurement and marketing than any other function. They focus so much attention on growing and protecting the topline. Often, cost management or improving profitability fall into the second or third tier of priorities.

In our experience, every company has clients you must work with because of their size or strategic importance. You also have clients you want to work with, the ones with good predictable businesses and respectful relationships.

We think your goal should be to fit in both categories.

So let’s dive into the 5 reasons procurement can be the tip of your spear.

1. Resilience

Forward-thinking companies are seeking that elusive supply chain resilience.

In Supply Chain Management Review, Alberto Todeschini and Bas von Rooijen reiterate much of what I have been writing for years. In “Fortifying the Future: Procurement’s Role in Building Resilient Organizations,” they note that procurement is a “critical driver” in building resilient organizations:

- Supplier diversification: Particularly important for critical inputs, supplier segmentation and diversification dramatically decreases the chances of material shortages. Look for suppliers in different geographies. Look for suppliers of different sizes. You can use Pareto here – if inputs from 20% of your suppliers drive 80% of your profits, first concentrate on alternatives for those 20%.

- Collaboration: Prioritize relationships with key suppliers. As mentioned above, pay your bills on time. When buyers and suppliers work together, both parties benefit. You can collaborate on strategy and every aspect of your relationship. Better forecasting, planning and capacity management can strengthen your entire ecosystem.

- Negotiations: Negotiate service levels to allow for flexibility – on both sides. Define and agree upon options to scale up or down before the next disruption – which is coming right around the corner.

2. Optionality

Reason No. 1 flows beautifully into Reason No. 2: Optionality.

You supply chain leaders must build multi-relational networks rather than linear supply chains. Eliminate single-source supplier contracts that represent a single source of failure. Develop multiple sources to spread risk and vulnerabilities.

But just adding a few suppliers as mentioned in Reason No. 1 is not enough. You must follow key inputs all the way to the source.

In one case, I know of an appliance maker that sourced compressors from China and Brazil. Procurement shifted all compressor sourcing to Brazil to save about 11 bucks a piece on total delivered cost. (The shorter supply chain and quicker transit times more than offset the expense of producing in Brazil.)

So when COVID-19 hit, this company thought they could grab market share. Their competition sourced everything in China, which shut down.

The Brazilian supply of compressors lasted a week. Refrigerator production froze because the Brazilians sourced a critical compressor input from China.

So this appliance maker went from what they thought was a dual source supply chain to a single source supply chain – knowingly. But even its previous dual source was really a single source.

A well-diversified, multiple source supply chain must follow all the components and raw materials to their initial source.

Such details matter.

3. Sustainability

In “Tackling Sustainability in Procurement,” Marisa Brow reports that more than half of the companies in a survey have changed procurement processes at least moderately in the last five years. And 33% have changed procurement processes significantly, according to her article in the October 2023 issue of Logistics Management.

Crucially, three of the top 10 procurement objectives related to sustainability. Thirty-five percent mentioned improving social responsibility (including ethical labor and working conditions). Twenty-eight percent listed protecting against risks that include environmental concerns, and 20% listed reducing greenhouse gas emissions.

In our view, those numbers should be higher.

Sustainable procurement is necessary to commit your business to long-term viability, create a stronger connection between a company’s values and its actions. Sustainable procurement supports the circular economy and reduces waste.

And true sustainable procurement could generate more positive media coverage than any amount of marketing hype.

4. Innovation

Procurement can facilitate innovation by championing cutting-edge technologies.

Procurement experts can evaluate technologies. Artificial intelligence, robotics, digital twins, Internet of Things (IoT), robotic process automation (RPA) and digital tools for sharing information must go beyond the hype. Digital supply chain networks and other technologies must deliver true benefits.

The right technologies enable digital transformation that supports collaboration, data analysis and real-time decision-making. The right technologies actually streamline processes, enhance efficiency and unlock new capabilities.

Procurement professionals can be key drivers to lowering the barriers to innovation. Removing bureaucratic hurdles can make it easier for teams to experiment with new ideas, approaches and technologies.

That innovation can help your organization challenge the status quo.

5. Nearshoring and Friendshoring

Today, the yin and yang of globalization vs. deglobalization has many companies looking at ABC – “anywhere but China.”

No, they are not leaving China. Absent a shooting war or a blockade of Taiwan, China will remain a key player in global supplier relationships. But forward-thinking procurement officers are looking for geographic proximity when purchasing new inputs and selling more outputs:

- 38% of companies buy most key inputs from regional suppliers. By 2026, 65% of all companies intend to buy most key inputs from regional suppliers.

- 43% of companies produce and sell most of their products in the same region. By 2026, 85% of companies plan to produce and sell most of their products in the same region.

This, of course, means more nearshoring, friendshoring and reshoring.

Nearshoring relocates production and sourcing to nearby countries, often within the same region or hemisphere. Reshoring brings manufacturing back to a company’s home country, while friendshoring involves sourcing from allied or friendly nations.

All three can reduce lead times and transportation costs – unless your friends are on the other side of the world, of course.

But as we know, globalization and deglobalization wax and wane. Yes, companies deglobalize (move toward a less integrated world) from one part of the world. But they then must globalize (move toward more interdependent economies) in other regions.

That interdependence requires logistics. So Western companies are redesigning global supply chains to center more on the Western hemisphere. That sets the stage for the Dominican Republic to transform into a supply chain hub, a gateway to the West.

The Dominican Republic is strategically positioned along major East-West and North-South trade routes in the Americas. It can support two-day shipping to 60-70% of the U.S. population. Its proximity to the U.S. and Latin America could cut lead times, inventory carrying costs and cash-to-cash cycles.

Procurement Done Right Can Drive Prosperity

In today’s world where disruption is the new normal, you must make procurement more than a back-office function. It’s the tip of your spear, leading the charge in driving resilience, optionality, sustainability, innovation and strategic geographic shifts. By leveraging procurement’s potential, your company can navigate the complexities of global markets, mitigate risks and seize new opportunities.

Remember, procurement is more than cutting costs. Procurement done right creates value, fosters relationships and positions your organization for long-term success. Whether it’s building a more resilient supply chain, championing sustainability initiatives or spearheading innovation, procurement can be your strategic differentiator.

So, sharpen your procurement practices. Empower your procurement teams. Make procurement the tip of your spear, guiding your company toward a better future.

In the end, how you procure may well determine how you prosper.

Related Reading

- Sourcing and Procurement in the Face of Perpetual Disruption

- Supply Chain Segmentation Helps Conduct Beautiful Music

- How 5Ls Make a Western Hemisphere Logistics Hub

- The Circular Economy Can Boost Supply Chain Resilience

Chief Procurement Officer Aaron Alpeter is a serial entrepreneur who has built a portfolio of supply chain and supply chain tech companies and is active in the North American startup ecosystem. He has successfully spearheaded dozens of startups that have created over $3 billion in investor value. A seasoned leader, he has built manufacturing relationships in North America and Asia across diverse business categories.