A Link in a Chain Is Not Enough for Competitive Advantage in Today’s Market

Sometimes, supply chain innovation is as simple as adding a third fulfillment center. Bam – with the right geographic locations, these three sites allow you to deliver 92% of your orders in two days or less.

Sometimes, it’s more complex.

Right now, 3PLs (third-party logistics providers) are facing a range of market complexities. Customers rarely “stick” for more than a few years. Labor is scarce. Customers favor 3PLs who can move beyond the transactional relationship, become partners and achieve end-to-end supply chain control.

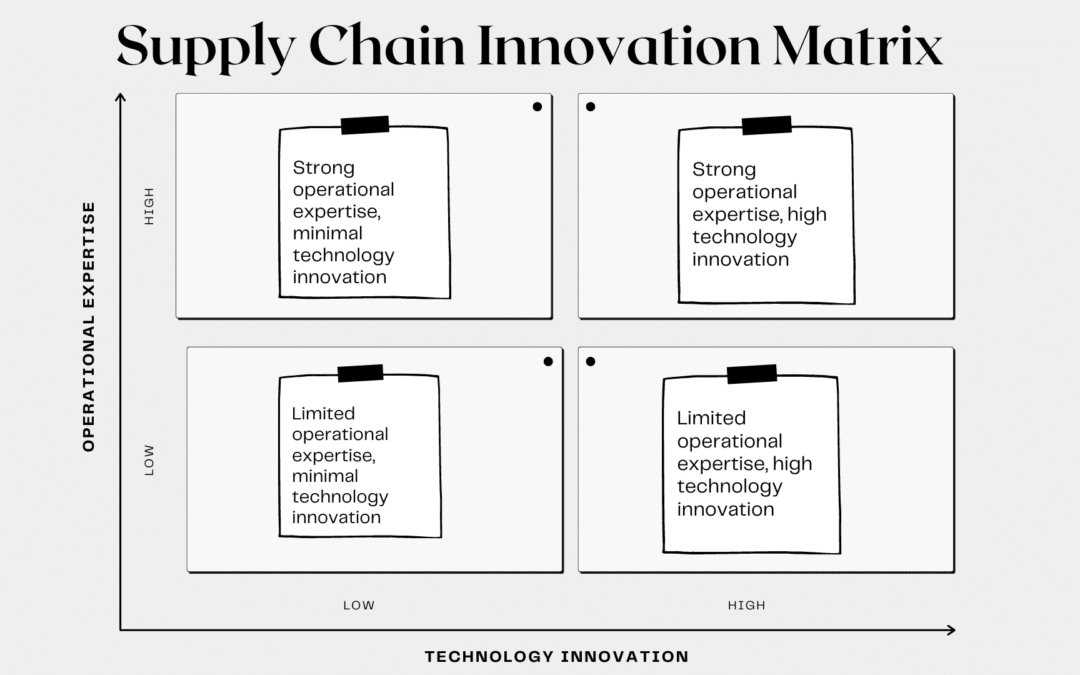

To conquer that market, 3PLs need to reach the northeast quadrant of what I call the Supply Chain Innovation Matrix. 3PLs in that quadrant possess excellent operational expertise and technology innovation.

That is the quadrant of supply chain resilience. 3PL solutions that can enable great results include supply chain technology like control towers and logistics technology apps for flexible labor.

Supply Chain Innovation Matrix, Southwest Quadrant

3PLs with limited operational expertise and minimal technology innovation populate the lower left, southwest quadrant of the Supply Chain Innovation Matrix.

These 3PLs have no ability to handle optionality – the ability to pivot to viable solutions when disruptions happen. And as we all know, markets these days face perpetual disruption.

Soon, those 3PLs are going to be discussing the good old days when they were profitable.

These supply chain players will write proposal after proposal after proposal. But they won’t win. 3PLs with limited operational expertise and minimal technology innovation are in heaps of trouble.

Supply Chain Innovation Matrix, Northwest Quadrant

3PLs with strong operational expertise but minimal technology innovation populate this region.

These 3PLs are working hard. But without the right supply chain technology, even the best workforce lacks real-time information. Experience will not help when systems cannot offer end-to-end supply chain visibility more than one or two links up or down a supply chain.

In this quadrant, 3PLs win on price. But the second someone comes in at a nickel less, you’re out of there.

That’s not sustainable. 3PLs already struggle to retain customers.

Supply Chain Innovation Matrix, Southeast Quadrant

3PLs in the lower right, southeast quadrant are great at technology innovation.

That’s interesting, but 3PLs without operational expertise will not be able to adapt to change quickly enough. And change comes almost daily in a world of perpetual disruption.

They might have the right data and the right information. But they will not know how to deploy optionality.

These 3PLs will win the work, but again, there’s no stickiness. A year or three later, customers will find another 3PL.

These are the kind of 3PLs that generate 10% of their revenue in new business every year. But their revenue only grows by 1% a year.

Why? They leak away 9% of their business every year.

All the supply chain technology in the world won’t save 3PLs with limited operational expertise.

Supply Chain Innovation Matrix, Northeast Quadrant

3PLs in this quadrant have great operational expertise and high technology innovation.

This is the quadrant of supply chain resiliency.

That’s where you’re going to give the customer more than they asked for. They’re going to love you, and you will become a trusted advisor and an extension of their team.

They’re going to invite you in and show you their strategic plan for next year. They want to explain where they’re headed because they need your help to get there. They need your operational expertise and your technology innovation.

And that’s where 3PLs want to be. That’s where resilience lies. Strong technology innovation and strong operational expertise.

To reach this quadrant, control tower technology is necessary. And adaptable labor can help.

What Is A Control Tower?

Control towers allow 3PL inventory management across networks, not just in your warehouse. Control towers help 3PLs synchronize supply and demand while dealing with uncertainty and minimizing cost.

That is the goal of supply chain.

For that to happen, first off, you need visibility. What the heck is going on? You must know shipment and inventory location in real time, product status, whether it will arrive an hour early, an hour late – or perhaps never.

Second, you must know how to respond when visibility changes. In today’s complex and evolving supply chains, artificial intelligence can manage most exceptions to plans and address them with optionality.

Control tower AI can look within the boundaries you have established. Often, the AI can determine what optionality you need to deal with real-time uncertainty.

AI only scales critical issues to humans. Things like a container arrival delayed from noon Tuesday to 4 p.m. Wednesday. Or a ship stuck off the coast for 15 days.

Those issues need to be understood and solved at the network level. After all, today’s supply chain networks comprise dozens, hundreds or even thousands or different enterprises.

For the last piece, 3PLs will need to execute that optionality. That means a network that lets all parties know what’s going to happen, what’s not going to happen, and who will do what tasks.

Think about the last time you were on an airplane. The airline’s goal is to get passengers safely to their location. How possible would that be without control towers? Unlikely.

3PLs that refuse to integrate control towers into their operations are like airplanes flying blind. Not an effective way to achieve competitive advantage in today’s market.

Supply Chain Innovation Example: A Control Tower in Action

Dock scheduling is a huge issue in America. People who discuss the issue usually blame the shortage of truck drivers.

As usual, what people talk about is not the real issue. The real problem? Truck drivers want to drive trucks, not spend one-third of their time waiting for a load or waiting to drop a trailer.

In some places, truck drivers who wait don’t even have access to a bathroom.

Perhaps that’s why estimates of driver turnover range from 19% to an alarming 94%.

The way to solve this problem? Real-time truck scheduling, where you know when those truckers will arrive and the right door to send them to.

That’s just one reason why 3PLs need a control tower.

Supply Chain Innovation Example: Flexible Labor in Action

One of my vice presidents had an interesting conversation with an Uber driver the other day. The driver had three jobs but limited interest in a full-time job.

He was learning to day trade in the morning. Then he would drive for Uber and Lyft in the afternoon or evening. Then he would fit audio engineering gigs in the gaps.

Task4Pros, a flexible labor company, specializes in finding people who want multiple income streams but optionality about when and where they work.

For example, many enterprises in Houston struggle to find labor. Task4Pros staffed an entire warehouse in minimal time by connecting with people who wanted optionality over their own schedules.

They did not want to work full time at a warehouse. But enough wanted part-time, flexible work to handle all needed shifts.

This is an entirely new labor market you can tap into. Not having enough workers is the definition of not having operational expertise.

And since Task4Pros is app-based, it also qualifies as a logistics technology solution.

3PLs as Links? Obsolete. End-to-End Solutions Win

Historically, 3PLs have wanted to be links in a supply chain. They did not want to look at end-to-end solutions, offer supply chain visibility or get involved with the digital management of shipments.

They hired full-time staff, maybe augmented with a few part-timers, and that was that.

Both of those must change if 3PLs want to reach the supply chain resiliency quadrant of the Supply Chain Innovation Matrix.

Innovation in supply chain is important. A control tower and flexible labor can help. Tompkins Ventures has the partners for both.

I would love to discuss your supply chain and logistics technology opportunities with you.

Related Reading

- Avoid 3 Common Mistakes When Creating a 3PL Relationship

- 3 Buckets to Help You Reinvent Work

- 4 Ways 4PLs Cut Your Logistics Costs – No. 3 is Gold!

- Walmart’s Fantastic Supply Chain Sourcing Concept

Jim Tompkins, Chairman and founder of Tompkins Ventures and Tompkins Solutions, is an international authority on designing and implementing end-to-end supply chains. Over five decades, he has designed countless industrial facilities and supply chain solutions, enhancing the growth of numerous companies. Jim earned his B.S., M.S. and Ph.D. in Industrial Engineering from Purdue University.

I have no idea how I ended up here, but I thought this post was fantastic. I am uncertain of your identity, but if you are not already a famous blogger, you are surely on your way to becoming one. Cheers!