How many things do you throw away every day that you and your businesses could reuse?

Laser printer cartridges, packaging, shoes, furniture, tires and more get tossed without a second thought. But in this age, your consumers, particularly younger ones, care about ESG (environmental, social and governance issues). Therefore, companies – and supply chains – are turning toward the Circular Economy.

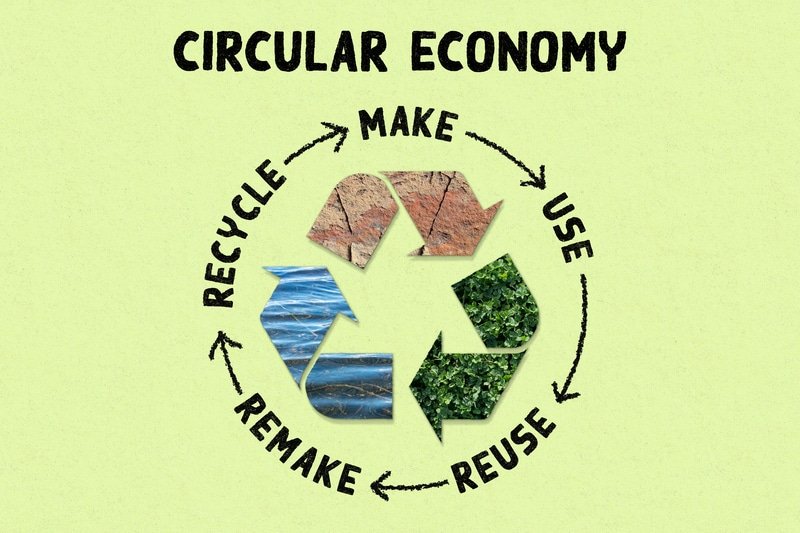

Traditional linear production uses raw materials to make products that consumers eventually throw away. The Circular Economy, according to the Ellen MacArthur Foundation, reuses, repairs, remanufactures and recycles products and materials. That keeps products and parts in circulation far longer.

Leaders Look toward Circular Supply Chains

As Karen Kroll reported for Inbound Logistics, 74% of supply chain leaders expect to increase profits in the next two years by applying circular economy principles. And reusing recaptured raw materials boosts supply chain resilience in a world where you need optionality more than ever. This reuse reduces your supply chain’s reliance on virgin materials that come from far-flung sources.

Kroll’s article includes examples from Lexmark and Xerox (printing and imaging products), Fernish (furniture and décor), Returnity (packaging) and HILOS (shoes). Virginia Tech is working on a project funded by the REMADE Institute on processes that retread commercial tires. According to SME, Caterpillar remanufactures mining and agricultural machinery, and GE Healthcare remanufactures imaging equipment.

Re-engineering supply chains – indeed, re-engineering the entire way you do business – will be key to using the Circular Economy. That can turn ESG into gold. Your team needs to design products with reuse and remanufacturing in mind. You need new locations for repairing, remanufacturing and managing waste. Your procurement processes can even look for outside sources of circular materials. Your partners, especially suppliers and distributors, also play a role.

Sustainable Packaging Works for Internal Logistics

For instance, getting consumers to return packaging could be a tough sell, but, Kroll noted, reusable packaging has proven viable in internal logistics, particularly between distribution centers and stores. And remember, reverse logistics is not the same as forward logistics – it’s a completely different omnichannel.

Companies that are succeeding in this arena increase their sustainability, benefit from shorter and compact supply chains, and learn more about how customers use their products.

The more time I spend on this Earth, the more I realize that the only constant is change. Forward-thinking businesses are changing the entire PLAN, BUY, MAKE, MOVE, DISTRIBUTE and SELL proposition to include the Circular Economy.

You can get on board and be the change or wind up left behind by tomorrow’s consumers.

Jim Tompkins, Chairman and founder of Tompkins Ventures and Tompkins Solutions, is an international authority on designing and implementing end-to-end supply chains. Over five decades, he has designed countless industrial facilities and supply chain solutions, enhancing the growth of numerous companies. Jim earned his B.S., M.S. and Ph.D. in Industrial Engineering from Purdue University.

Absolutely! I am so happy to see thought leaders like yourself embracing and supporting a circular economy. This must be a large part of our future. Thank you for sharing and promoting these thoughts!!